Project Description

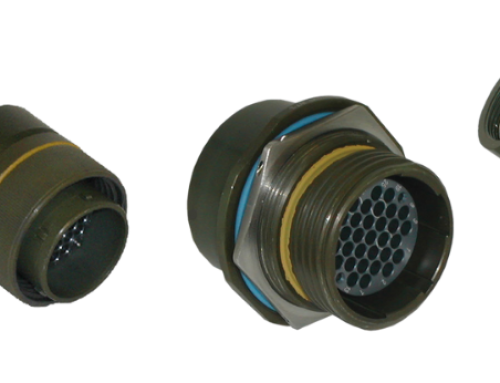

M83522 MIL-ST connector

For Military and Industrial Use

Physical Contact Connectors – MIL-ST Connectors

Amphenol Fiber Systems International (AFSI) offers rugged military fiber optic ST connectors for deployable and fixed communication system requirements. AFSI’s connectors are designed to provide the best possible optical performance in applications with severe environmental conditions.

Various versions of connectors and adapters are available to meet a broad range of specific needs and system requirements. The M83522 connector is qualified for military applications and features a higher spring force than commercial ST connectors, allowing it to meet the shock requirements of MIL-DTL-83522.

Commercial-Off-The-Shelf (COTS) ST connectors provide the same robustness with a spring force more consistent with commercial ST connectors, enabling them to connect effectively with other ST connectors and ancillary electronics.

Features

- Super and Ultra-PC polish capabilities

- High grade stainless steel body with zirconia ceramic ferrule and fungus-resistant self-extinguishing boot

- Superior optical performance in extreme environmental conditions

- MIL-qualified series: high spring force for shock and vibration resistant critical in military applications

- Navy approved COTS: for moderate shock and vibration environments

Applications

- US Navy shipboard, surface and submarine, mission critical combat and communications systems

- Mobile tactical shelters

- Electronic battlefield networks

- Mobile emergency telecommunication stations

- Deployable outdoor, harsh environment

Material

- Ferrule: zirconia

- Body: stainless steel

- Boot: fungus resistant, self-extinguishing thermoplastic

Options Available

- M83522/16- DNX, – DNY

- M83522/17- NY

Specifications

| Description | Measurement/Detail |

| Insertion Loss | < 0.75 dB (MIL-C-83522 allows for <1.0 dB) |

| Return Loss | > 30 dB (multimode) |

| Tensile Loading | > 230 N |

| Mating Durability | > 500 cycles |

| Impact | 8 times, 1.5 meters |

| Dust | MIL-STD-202, Method 110 |

| Thermal Shock | MIL-STD-1678, Method 4020 |

| Vibration | MIL-STD-1344, Method 2005 |

| Temperature Humidity | DOD-STD-1678, Method 4030 |

| Salt Spray | MIL-STD-1344, Method 1001 |

| Flammability | MIL-STD-1344, Method 1012 |

| Temperature Cycling | -55oC to 125oC Op, -65oC to +200oC Non-Op |

| Shock | MIL-STD-901D, Grade A, Type A, Class I |

| Fungus Resistant | MIL-STD-810, Method 508 |