Project Description

Optron

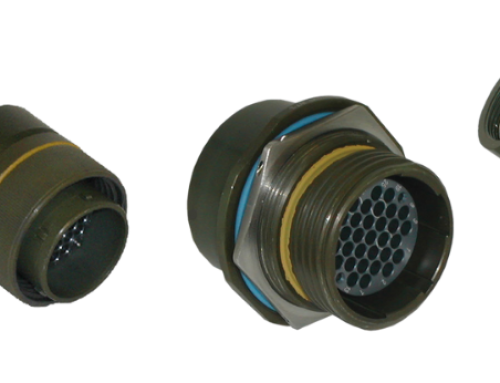

Physical Contact Connectors – Hybrid Connectors

Amphenol Fiber Systems International (AFSI) manufactures a complete line of circular hybrid connectors designed and qualified to MIL-PRF-28876, Rev. E. Optron connectors are precision-machined to stringent tolerances and designed to provide superior optical performance in extreme environmental conditions.The backshells feature the QuickLoc captivation system developed by AFSI, which is simple and easy to install by removing the captivated aramid yarn of the cable and recapture without cutting back the cable. The QuickLoc backshell also allows easy access to maintain or reconfigure termini without altering the captivated aramid fiber.

Features

- Precision-machined to MIL-PRF-28876, Rev. E specification

- Available in three shell sizes: 13 (4-ch), 15 (6, 8-ch), 23 (18, 31-ch)

- Inserts are interchangeable from plug to receptacle; either can be operated with pins or socket termini

- Operates with all qualified single mode or multimode M29504/14 and /15 termini

- Complete line of straight, 45 degree and 90 degree backshells

Benefits

- Backshell design allows simplified, removable aramid yarn captivation with no mechanical crimp rings

- Angled backshells use the same tools as the straight backshell

- QuickLoc design enables faster maintenance or repair without complete disassembly of connector backshell assembly

Options Available

- Materials: aluminum, stainless steel & brass

- Finish: black anodize over aluminum (only)

Certifications

- Mining Safety Health Administration (MSHA) pending

Applications

- Mining

- Oil & gas

- Industrial

Specifications

| Description | Measurement/Detail |

| Mating Durability | 500 cycles per EIA-455-21 |

| Thermal Cycling | -40°C to +85°C per DoD-STD-1678, Method 4010 |

| Corrosion Resistance | 500 hour salt spray MIL-STD-1344, Method 1001 |

| Ozone Exposure | Per MIL-STD-1344, Method 1007 |

| Fluid Immersion | Per MIL-STD-1344, Method 1016 |

| Crush Resistance | 7 tests @ 1250 Newton per MIL-STD-1344, Method 2008.1 |

| Maintenance Aging | Per MIL-STD-1344, Method 2002 |

| Terminus Retention Force | 22 lb min. per MIL-STD-1344, Method 2007 |

| Insert Retention Axial | 100 PSI min. per MIL-STD-1344, Method 2010 |

| Cable Pull Out Force | 162 lb min. per EIA-455-6 |

| Cable Sealing Flexing | Per MIL-STD-1344, Method 2017 |

| Impact | Per MIL-STD-1344, Method 2015 |

| Flammability | Per MIL-STD-1344, Method 1012 |

| Operating Temperature | -54°C to +65°C |

| Storage Temperature | -62°C to +70°C |

| Typical Insertion Loss | 0.4 dB nominal multimode, 0.5 db nominal single mode |

| Connector & Backshells | Aluminum alloy, CAD plate, anodize black plating, 316L stainless steel, 303 stainless steel & brass 360 alloy no. C36000 |

| Cable Sealing Strain Relief | Polyolefin, self encapsulating |